laboratory use airflow grinding mill

| Price: | 10000.0 USD |

| Payment Terms: | T/T,WU,Paypal |

| Place of Origin: | Sichuan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Application: laborratory use

MOQ: 1 set

Port: Chengdu

High efficiency and energy savig for laboratory's materials crushing

Easy-handling

High efficiency and low energy consumption grinding mill for laboratory

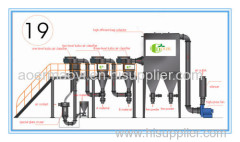

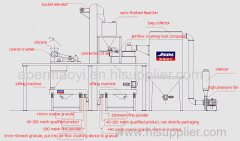

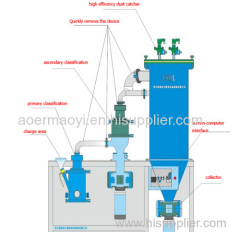

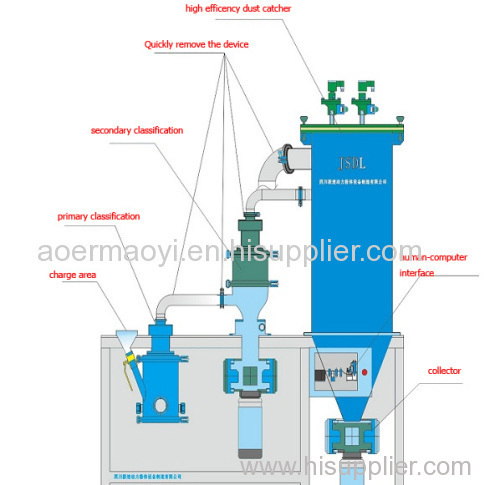

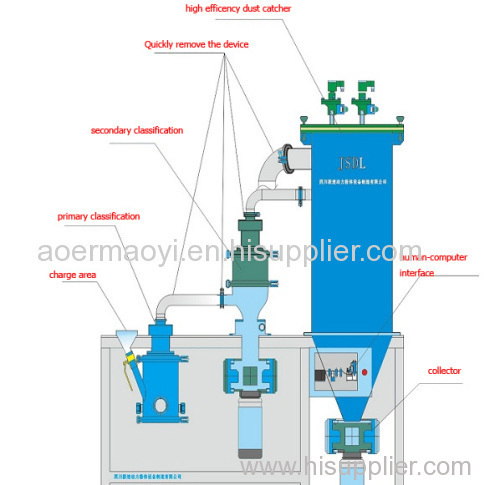

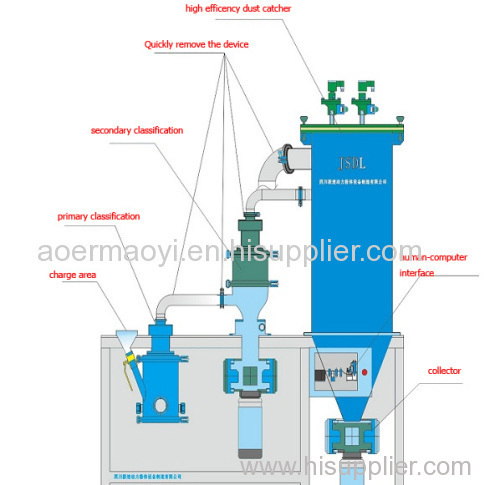

Working principle

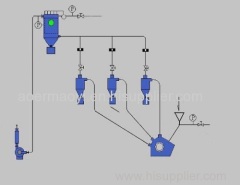

1. Material will be transmitted to crushing cavity by input material device, via the material impact, collision, friction, shear, extrusion with the high speed rotary device and particle to realize superfine grinding.

2. The crushed material will be rising to impeller grading machine by air flow, via centrifugal force and air pumping force, to achieve the separation of coarse and fine powder, fine powder is collected by the cyclone collector qualified, unqualified powder will be re-crushing thru inner grading machine. The purified gas is composed of a draught fan exclusion.

Characteristics:

It's a small experimental device specially designed for colleges and scientific research department, equipment has the advantages of small volume, compact structure, convenient assembly and disassembly. Break through the particle acceleration technology, greatly improve the grinding efficiency, and reduce energy consumption, avoid over crushing.

1 Can reach 2-74Um particle size, narrow particle size distribution and no large particles

2 Crushing by material collision, can process Mohs hardness of 1-10 particles, reduce abrasion, product without iron contamination

3 Reasonable cooling flow field in the grinding process, due to the rapid expansion of the air flow and air temperature is reduced, processing and especially suitable for heat sensitive, low melting point materials

4, Optimize the structure of equipment, improve equipment performance, can dissociation agglomeration of ultrafine powder, polymer dispersed effective.

5 Original classification flow technology, can obtain the crushing efficiency and tight size distribution best, smash granularity can be regulated arbitrarily between 1-74um, the smallest can reach sub micron, reduce material loss, can achieve the basic body cavity crushing material completely crushed, few equipment inner wall residual, no dead angle, easy to clean, fully meet the GMP standard

6 Original special jet and classification flow processing technology, suitable for adhesion material

7 Can perform species material mixing pulverizing, has good mixing function

8 Operation in sealed negative pressure, no environmental pollution

Technical parameter:

Model | Max feed size | Discharging size | Manufacture capacity | Install power | gas consumption |

JSDL-SYJ6 | <1mm | 2-80um | 500-5000g/h | <6-8.5kw/380v | 1m3/min |

JSDL-SYJ7 | <1mm | 2-80um | 500-5000g/h | <6-9kw/380v | 1m3/min |

JSDL-SYJ8 | <1mm | 2-80um | 0.5-10kg/h | <18-20kw/380v | 1m3/min |

About factory

1.Factory -located in Mianyang, Chinese people's liberation army 63820,575 workshop.

2.Quality -powerful military aerospace strength, the machine can operate 29 days continuously without rest.

3.Engineer-our engineer are both air power ultra expert with overall R&D strength and comprehensive competence, which can design the jet mill or redesign mill according customers' requirements.

Service

we have professional sales team for pre-sales and after-sales services, also we will send engineer to your factory if you need.

We believe that our perfect products and excellent services will establish a win-win business relationship with you.

Contacts: rena

Skype: renazhang123

Tel: 0086-15378196817

Chengdu OUR Trading Co, Ltd

Related Search

Find more related products in following catalogs on Hisupplier.com

Related Products

Company Info

You May Like:

Product (424)

- other equipment (43)

- Grinder for multifunctional (120)

- Grinder for industry (196)

- Grinder for medicine and food (65)

.jpg)