hot sell airflow machine for laboratory and scinetific research department

| Price: | 100000.0 USD |

| Payment Terms: | T/T,WU |

| Place of Origin: | Sichuan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Laboratory use airflow crushing machine

2. samll machine

3. certificate special patent

4. airflow crushing

5.shipping by sea

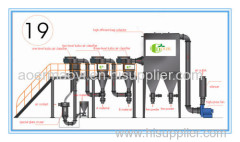

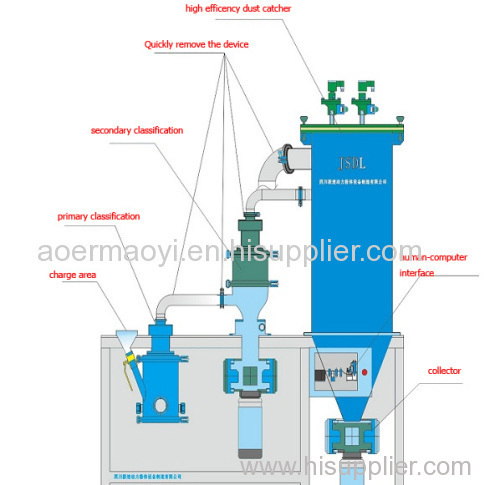

Working principle:

Material will be transmitted to crushing cavity by input material device, via the material impact, collision, friction, shear, extrusion with the high speed rotary device and particle to realize superfine grinding.

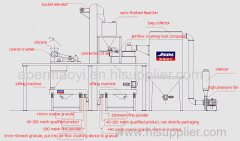

Characters:

Is a small experimental device specially designed for colleges and scientific research department, equipment has the advantages of small volume, compact structure, convenient assembly and disassembly. Break through the particle acceleration technology, greatly improve the grinding efficiency, and reduce energy consumption, avoid over crushing.

Application:

Apply for all kinds of material.

Advantages of the equipment:

1 can reach 2-74Um particle size, narrow particle size distribution and no large particles

2 crushing by material collision, can process Mohs hardness of 1-10 particles, reduce abrasion, product without iron contamination

3 reasonable cooling flow field in the grinding process, due to the rapid expansion of the air flow and air temperature is reduced, processing and especially suitable for heat sensitive, low melting point materials

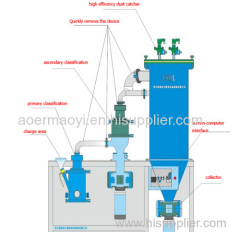

4, optimize the structure of equipment, improve equipment performance, can dissociation agglomeration of ultrafine powder, polymer dispersed effective.

5 original classification flow technology, can obtain the crushing efficiency and tight size distribution best, smash granularity can be regulated arbitrarily between 1-74um, the smallest can reach sub micron, reduce material loss, can achieve the basic body cavity crushing material completely crushed, few equipment inner wall residual, no dead angle, easy to clean, fully meet the GMP standard

6 original special jet and classification flow processing technology, suitable for adhesion material

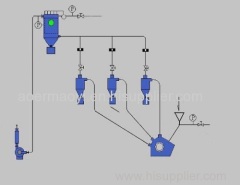

7 can perform species material mixing pulverizing, has good mixing function

8 operation in sealed negative pressure, no environmental pollution

technical parameters:

Model | Max feed size | Discharging size | Manufacture capacity | Install power | gas consumption |

JSDL-SYJ6 | <1mm | 2-80um | 500-5000g/h | <6-8.5kw/380v | 1m3/min |

JSDL-SYJ7 | <1mm | 2-80um | 500-5000g/h | <6-9kw/380v | 1m3/min |

JSDL-SYJ8 | <1mm | 2-80um | 0.5-10kg/h | <18-20kw/380v | 1m3/min |

Service we can supply:

1. Support

We can not only provide the good machines, but also wholeheartedly provide the comprehensive for our clients. The series of professional technology service will make you have an excellent product experience.

2. After-sales service support

After we signed the purchase contract and have a certain reputation guarantee, we will contact the professional group that responsible for ship bookings, commodity inspection, commercial invoices, packing list, insurance policy and so on, in order to provide you the perfect goods trading services, until the product you purchased properly to your hands.

We will send a professional and high levels installation engineer team at the same time the product properly to the destination, in order to supply you a full range of products installation services. For some typical problems, our rigorous installed engineers also will do some certain installation debugging training, etc.

Technological support:

JSDL has been largely adopting new technologies, new techniques and high-tech equipments. And JSDL also has strict and effective quality control system.

JSDL insists on providing clients with overall solutions from equipment recommendation to debugging and installation, worker training, technical support and maintenance.

Finished product:

factory show:

certificate & patent

Contact information:

contact person: Sunny

tele/fax: 0086-28-61318297

skype: wu.yao5

more details welcome to contact me !

Related Search

Find more related products in following catalogs on Hisupplier.com

Related Products

Company Info

You May Like:

Product (424)

- other equipment (43)

- Grinder for multifunctional (120)

- Grinder for industry (196)

- Grinder for medicine and food (65)

.jpg)